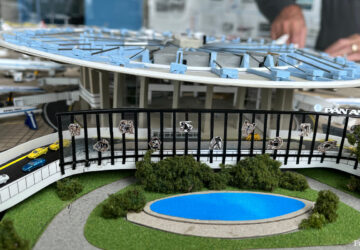

The Tulip at Embarcadero Center Four

The Tulip at Embarcadero Center Four

As we learned last week, concrete began as a structural component of architecture. A mixture of cement, aggregate and water, concrete has been used as a building material for over a millennia. It was only in the 1920s, however, that technical innovation allowed for precast concrete to become an acceptable substitute for stone in architectural ornamentation.

Moreover, by the late 1950s, precast concrete was a direct competitor with metal-and-glass curtain wall systems. Architectural precast concrete is a broad term for concrete that is colored, shaped, finished or textured for architectural effect. Its appearance can be altered through techniques such as sandblasting, acid washing, high-pressure water washing or polishing. It can be used for load-bearing or non-load-bearing walls, and can be either reinforced or pre-stressed. Precast concrete is typically manufactured at an off-site plant rather than on a construction site. Concrete is poured into molds. The resulting products are trucked to the construction site where they are assembled into a final structure.

Some of the more innovative examples of precast concrete can be found in San Francisco.

Architect William Perriera’s Transamerica Pyramid is considered one of the 50 most significant precast concrete projects in the United States. The use of precast concrete during its construction in 1972 marked an historical engineering and construction moment. The precast concrete faà§ade of this 48-story building is made up of 3,920 pieces bolted to the building’s structural system. The crushed quartz added to the precast concrete helped the building win a Platinum LEED certificate in 2011 with a 62 Solar Reflex Index.

The Peace Pagoda, a five-tier concrete stupa designed by Japanese architect Yoshiro Taniguchi, stands as a beacon to San Francisco’s Japantown. Financed with an $185,000 gift from sister city Osaka, the pagoda was built in 1968 by East Bay Precast Concrete Company Terracon.

The Ramp of the Tulip at Embarcadero Center Four

The Ramp of the Tulip at Embarcadero Center Four

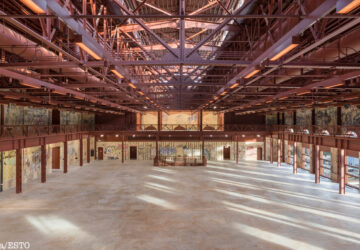

The Tulip, designed by architect and developer John Portman serves not only as the centerpiece to his Embarcadero 4 building, but as a ramp to move between the three exterior floors. The petals were precast by Western Art Stone. Once on the jobsite, they were assembled by Dinwiddie Construction Company over a wooden structure and attached to the poured-in-place center core. The ramp was poured-in-place as well.

Precast concrete is far less expensive than carved stone, it can mimic details just as beautifully, and also gives you the ability to make multiple copies inexpensively. The use of concrete will continue to add flourishes to modern architecture, as long as architects look at the material as something more than a basic building block.

Follow Untapped Cities on Twitter and Facebook. Get in touch with the author @PQPP3.