All images courtesy Arthurious

All images courtesy Arthurious

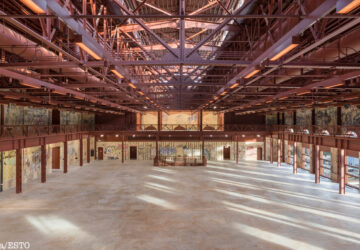

As urban explorers, we strive to get an insider’s peek at some of the most inaccessible and interesting places New York City has to offer. That’s why we were beyond thrilled when Arty, the editor-in-chief at Arthurious shared some photos he took during a behind-the-scenes tour of the New York Times printing plant in Queens. While there, he was given the opportunity to look at the design process and the people behind the making of what has become the largest combined print-and-digital circulation of any daily newspaper in the United States. Here’s a look at what was inside:

I’ve been a New York Times subscriber for as long as I remember — like magic, every Saturday morning a hefty stack of freshly printed newsprint sheets arrive at my doorstep. I settle in the most comfortable chair in the house (my Muji bean bag) and flip through the sections of the paper — accompanied by a double espresso. Magic aside, I have often wondered how each and every section of the paper comes about in such coordination, when are the last edits sent to print, and how does the paper arrive to each subscriber’s doorstep, rain or shine.

On a Thursday evening, instead of popping into a gallery afterparty, I found myself in front of a large lit warehouse in Flushing, Queens — it was 10 p.m. and the presses at The New York Times’ printing facility had just begun printing tomorrow’s paper.

Rolls of newsprint paper stacked and stored in a large warehouse. Each roll is 10 miles long and makes 30,000 newspapers

Rolls of newsprint paper stacked and stored in a large warehouse. Each roll is 10 miles long and makes 30,000 newspapers

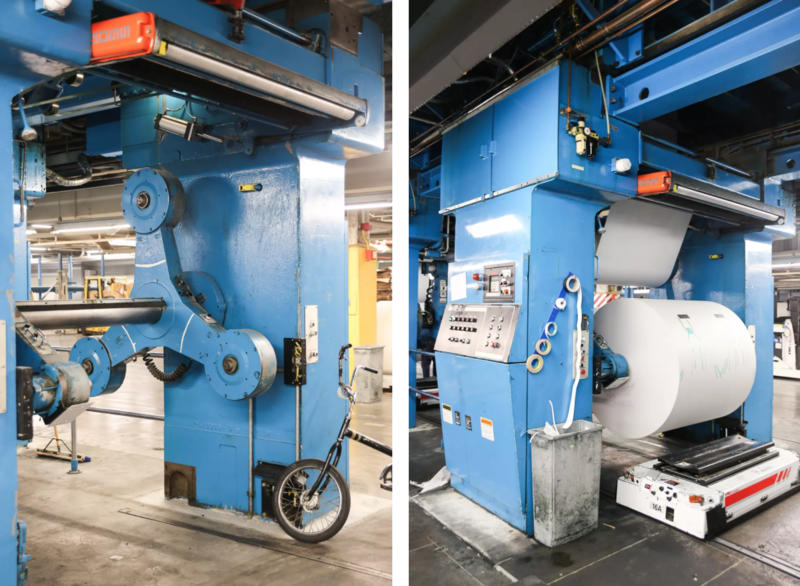

Production happens on two levels. Here, on the lower level, machines pull the newsprint roll up to the presses

Production happens on two levels. Here, on the lower level, machines pull the newsprint roll up to the presses

Newsprint rolls are transported by the robotized vehicles

Newsprint rolls are transported by the robotized vehicles

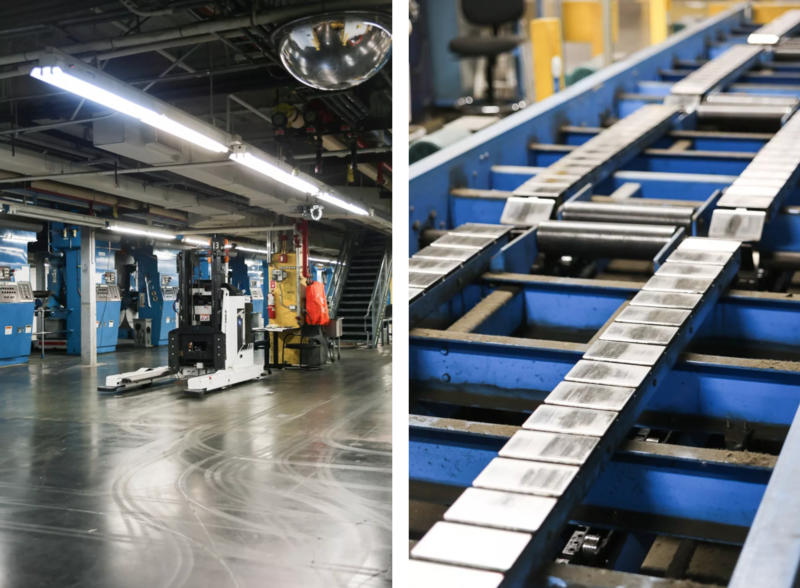

Upstairs, the press towers print almost 250,000 newspapers a day

Upstairs, the press towers print almost 250,000 newspapers a day

Operator’s favorite section

Operator’s favorite section

To print that many newspapers a day massive amounts of ink are stored in large containers and transported to each printing press in metal pipes

To print that many newspapers a day massive amounts of ink are stored in large containers and transported to each printing press in metal pipes

At press check, a proofing table with a special ruler marks the position of columns on each page

At press check, a proofing table with a special ruler marks the position of columns on each page

The plates that the presses use need to be custom made in a special room. The yellow lighting protects them from getting struck

The plates that the presses use need to be custom made in a special room. The yellow lighting protects them from getting struck

Plates that are ready to go to press are stored on the wall

Plates that are ready to go to press are stored on the wall

The daily papers are then packed to be delivered the same night, just before sunrise

The daily papers are then packed to be delivered the same night, just before sunrise

High tech control room that tracks and manages the entire operation from plating to printing, to collating, and packing

High tech control room that tracks and manages the entire operation from plating to printing, to collating, and packing

If you enjoy learning about design process and manufacturing, see more of Arthurious’ tours like the one from Steinway Factory in Queens, and a bagel factory in the Bronx. For live updates, follow Arthurious on Instagram, Twitter and subscribe to a weekly culture newsletter.

Next, check out The Ghosts of Newspapers Past: 15 Former Locations of NYC Newspaper Headquarters and The History of NYC’s Newspaper Row, the Former Epicenter of News.