NYC’s Forgotten ‘War on Christmas Trees’

Discover how an obscure holiday crackdown affects festive street vendors today!

Steinway & Sons is an undoubtedly distinguished name for pianos, but unless you’re a musically inclined New Yorker, it may not hold particular significance. You might remember the shiny black veneer of your high school concert piano with the gold “Steinway & Sons” logo, or Queens locals might think of the prominent Steinway Street that runs through Astoria and Long Island City.

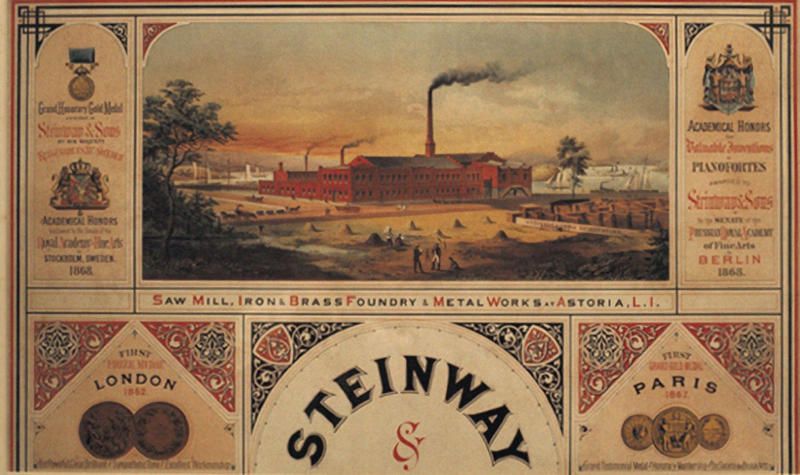

But the piano company Steinway & Sons actually has a significant New York City history, and its factory, originally established in the 1870s, is still standing in Northern Astoria toward the edge of the East River. Though only parts of the current factory are original buildings dating back to the 1870s, and what used to be two distinct and separate factories in Astoria has been consolidated into one, workers inside are still meticulously crafting each piano by hand, following the highest quality procedures as they did 160 years ago.

It all began in 1850, when piano maker Heinrich Engelhard Steinweg (to become Henry E. Steinway) immigrated to America with his children. In 1853, embracing the new American entrepreneurial spirit, he and his sons formed Steinway & Sons, where they worked tirelessly to improve the European piano and create the best version of the instrument possible.

On a recent tour of the Steinway Piano Factory, we discovered just how precise the process still is, and learned some of the most fascinating secrets lurking beneath each piano’s keys…

Image courtesy of Steinway & Sons

When the Steinway Factory was originally built in Astoria, there was no nearby housing. To ensure workers didn’t have to commute to the facility from Manhattan or other areas with housing, the company constructed surrounding rowhouses where workers lived. Some of these original buildings can still be seen on 20th Ave. and 41st St. in Astoria. You can tell by looking up at the cornerstones of the buildings for engraved street names (streets used to be named after the workers themselves, like Charles St., etc.).

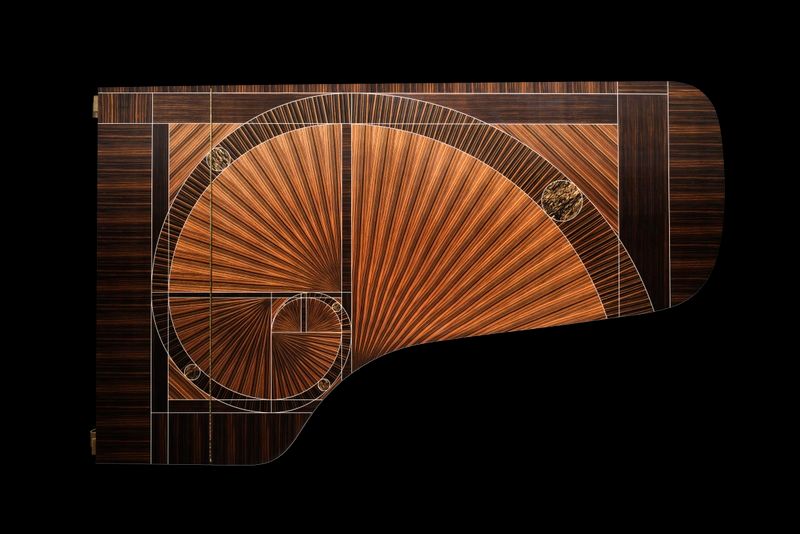

Photo courtesy of Steinway & Sons

Steinway & Sons has made a special, significant piano for each milestone so far. A specially designed 100,000th piano was gifted to the U.S. White House in 1903, and is now part of the permanent collection at the Smithsonian. The 300,000th piano was presented to President Franklin D. Roosevelt in 1938, and still currently resides in the East Room of the White House. The 600,000th piano, released in 2015 and designed by master artisan Frank Pollaro, was called the “Fibonacci” and was handcrafted using natural Macassar ebony. Who knows what the next 100,000 pianos will have in store!

Through a combination of trial and error, experimentation and cutting-edge acoustic sciences, Steinway and his family were able to establish some of the most fundamental elements and production techniques for creating the best-sounding pianos in the world. For example, at the time, the bass and treble strings in a piano would often snap while a pianist was playing on stage because of the severe tension, and it would have to be replaced by another piano mid-performance. Steinway perfected the cast iron plate (or “harp”) that sustains this tension. It was originally made out of wood, which could not withstand the high tension required to create the volume needed by concert pianos to be heard above a symphony orchestra.

Steinway also perfected the “over stringing” process (stringing the bass strings over the treble), which improved tonal quality and length. But one of their most well-known patents was the “single piece bent rim”—the creation of which you can see on the factory tour—which is the bending of long pieces of layered hard rock maple (over 20 feet long for a concert grand) that establishes the initial shape of the piano and is bent on a press into its final shape.

Each rim press is custom for its specific piano model, and there is only one press for the “Model D,” or famous Steinway “Concert Grand” piano. That means the concert piano in your high school auditorium was made in the same place and touched the same spots as the piano Billy Joel played at Madison Square Garden last month!

After the rims are pressed, they are stored in a climate-controlled conditioning room for months. This “rim conditioning room” is very hot and humid, allowing the moisture introduced from the glue during the rim bending process to come out of the rim at a controlled pace. The end result is a precise moisture content at which point the rim is ready to continue on its journey of becoming a Steinway piano. Additionally, time in the room allows the rim to acclimate to its new shape. Although rims coming out of the room look identical to those going in, there have been minor adjustments in the shape undetectable to the eye that have happened as the rim settles into its new shape. Steinway needs those minor adjustments to happen before the process of building a piano within that rim continues.

A special “case number” on each piano helps workers keep track of its specific needs, as “each piano is its own unique person,” Marketing & Communications Director Anthony Gilroy said.

Every step of the Steinway piano-making process is by hand — from the rim bending, to installing the cast iron plates, to stringing, to mating the “action” (the part with the keys) to the piano base itself — so much so that the piano “factory” resembles more of a woodworking shop than traditional factory set up. The factory can output anywhere from 5 to10 pianos a day, or between 1,500 and 2,000 per year. From start to finish it can take up to 11 months to make one piano. It makes that six-figure price tag much more understandable.

Many of the workers at the Steinway & Sons factory come from countries with a woodworking background, like Prenta Ljucovic who came from Montenegro, a country in the Balkans. Prenta has worked at Steinway & Sons for over 45 years, making her the longest-tenured woman in the factory, and the only woman to ever work in the difficult “Case Making” department. This involves lifting, cutting, planing, sanding, drilling and shaping heavy blocks of solid wood to make the outer case of the piano.

The only place you can get a Steinway piano authentically restored is at the Astoria Steinway Factory, as the company doesn’t sell its parts (except standard replacement parts) outside of the factory. They restore between 100 to 200 Steinway grands each year. The “Restoration Center” at the factory has done some amazing projects — from restoring a Civil War era piano that had been hidden away in a barn, to working with Paul McCartney himself to restore an 1877 piano at the Motown Museum in Detroit.

Most pianists can tell if the “touch” of a piano is off, meaning they have to push harder on one key to reach the volume of the others (or vice-versa). Steinway workers meticulously test each key with small weights, then make small adjustments to the “action” (the mechanism between the keys and the hammers that strike the strings) and add proper counter-weights within the keys themselves to ensure an even “touch” across the entire keyboard.

The most recent example is the Spirio: a high-tech piano that plays itself. Connected through Bluetooth, this high resolution player piano comes programmed with a full music library (that you access on an accompanying iPad), recorded in Steinway & Sons Studios by over 1,700 Steinway artists, with new music, videos and playlists released each month exclusively. The piano is designed with same precision as any Steinway and is programmed to mimic the exact style of the playing artist. There is even music and videos from historical performances, so it’s like going back in time to a concert 100 years ago from one of the greatest musicians of all time, right in your own home.

Next, check out Photos Inside Steinway & Sons Piano Factory’s Secret Vault

Subscribe to our newsletter