Last Chance: The Annual Orchid Show Soars at the New York Botanical Garden

The vibrant colors of Mexico come to NYC for a unique Orchid Show at NYBG!

Just prior to New York State going on PAUSE for coronavirus, we went to visit Roosevelt Island‘s amazing pneumatic tube trash system. Below the streets, residential garbage is whisked underground and out of sight from apartment buildings to a central Automated Vacuum Assisted Compacting (AVAC) facility. Operated by the New York City Department of Sanitation, it is only one of two such systems in the United States at this scale (the other being at Disney World).

The visit proved timely, as New York City is just beginning to assess the impact the pandemic has on essential workers. For nearly half a century, Roosevelt Island’s residential trash has been handled without the need for curbside truck pickup, which in turns limits the need for workers to be out handling the garbage. During major disruptions in recent memory, like Hurricane Sandy and blizzards, trash collection continued uninterrupted on Roosevelt Island even when street collection stopped in the the rest of the city.

We visited the Roosevelt Island AVAC facility with Tony Pellegrino, Director of the Bureau of Building Maintenance at DSNY and Al Digregorio, the Chief Engineer of DSNY at the Roosevelt Island facility. Digregorio comes from three generations of sanitation workers and has long ties to this particular pneumatic trash system. “My grandfather started the sanitation workers union — John DeLury back in the ’30s ’40s,” says Degregorio, “Ten years later, my mother and her two brothers worked here. Then my mother married my father who worked here. And now I’m here! Three generations.”

If you live in a building on Roosevelt Island, you throw your trash out down chutes like in other high-rise apartments. But instead of the usual process — building staff processing the garbage, bagging it, and putting it on the street — the waste stays in an inlet until a sensor notes that the garbage has reached a certain level. The AVAC system automatically starts up, opens the valve, and sucks that garbage at 60 to 70 miles per hour through 20 inch underground tubes to the central facility. In total, the pneumatic waste system serves over 14,000 residents and more than two dozen buildings.

Buildings designed by Josep Lluis Sert, part of the original batch of residential buildings constructed on Roosevelt Island

Buildings designed by Josep Lluis Sert, part of the original batch of residential buildings constructed on Roosevelt Island

.

Pneumatic tube trash systems have the added benefits of being completely sealed, which means the system is flood resilient and you don’t get bugs or wildlife like rats infesting the garbage. Environmentally, there is no need for plastic bins in the basements of buildings or larger plastic bags to collect the garbage thrown by individual units. Additionally, the system reduces truck mileage traveled by 80% (and subsequently reduces the resulting greenhouse gas emissions).

In Disney World and in cities like Barcelona, separate collection points for garbage and recyclables are right on the street, and the tubes begin just below so you never have to see any kind of collection vehicle.

New turbines installed at the AVAC facility

The air stream that sucks the garbage through the system is powered by centrifugal turbines or air exhausters. In effect, they function like powerful fans that create a giant vacuum. Starting in 2019, the Roosevelt Island system got a $1.7 million upgrade by ENVAC which included new energy efficient fans and remote sensor monitoring. A visit into the fan room of the central AVAC facility shows that it only takes the one new installation of exhausters to make the same amount of vacuuming power as the three sets of exhausters that existed before. And whereas the system used to be operated manually through hand panels or manually through a computer, now the system operates either by using computer or on an automatic basis.

The former turbines

The waste arrives to the AVAC facility underground, traveling above ground within tubes you can see in the parking lot, and into collection silos. The garbage is then sent into one of two red cyclones inside the building that separate the waste from the air (with a rotary vane filter that catches the small, lightweight pieces of garbage), and then the garbage drops down into a compactor container.

The cyclone that separates the trash from the air stream

Inside the trash compactor container

Containers moving on the conveyor system

Containers moving on the conveyor system

Once that container is full, it gets rolled outside of the facility on a motor-driven chain conveyor system onto a truck which takes the garbage to a waste transfer point where it goes out by rail or barge to its final destination. (New York City sends all of its garbage to other states, where the city pays for its final disposal). Before the air is released out, it’s filtered to remove dirt particles and contaminants.

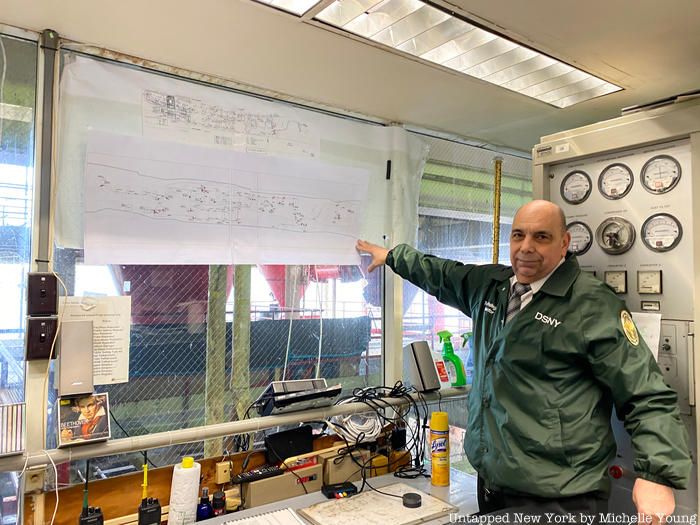

This whole operation is monitored from a control room, cantilevered above inside the facility. In the control room, you can see new and old technology side by side.

DSNY Director Tony Pellegrino in front of the map of the waste system on Roosevelt Island

Control board for the conveyor system

One of the issues of a tube system that transports garbage is due to what people sometimes throw in. Digregorio says “The biggest culprit of jams is when [residents] throw things in there they’re not supposed to — hangers, coat racks, car bumpers, trees, vacuum cleaners. Whatever they can fit in there, they’ll throw it.” These large objects get caught around the bends of the pneumatic tubes and jam up the system.

Today, the waste system is monitored through a modern computer program that shows sensor readings and other data

Jams can sometimes be removed by applying the full force of all the turbines, but this often just compacts the garbage tighter without releasing the problem. More reliably, using a technique devised by the engineers at DNSY, the team enters the system through manholes, send in long metal rods that have an anchor-like end to either break up the jam or retrieve the troublesome item. To get enough pull, the rod is attached to a winch on a vehicle that is driven to get the items out.

The Roosevelt Island trash system was created before the advent of recycling, so there is currently no way to have multiple streams of waste to handle recyclables (unless the system gets completely upgraded to have multiple transport pipes coming out of each building). Residential buildings deliver their recyclables to a central location outside the AVAC facility to place in specific dumpsters.The team at the AVAC facility says that no matter what, recyclables get into the waste stream and they attempt to separate out what they can.

Imagine a world in which New Yorkers no longer have to deal with garbage piling up on the sidewalks. Where we don’t have to send workers out multiple times a week into a pandemic to collect garbage or require building staff to process waste. In the era of coronavirus, the foresight of the Roosevelt Island trash system shows its benefits clearly. Half a century later, and with the recent upgrades, the system feels as futuristic as ever.

Next, discover the Top 10 Secrets of the NYC Department of Sanitation.

Subscribe to our newsletter