Artist-Led Tour of "ENCORE" Photo Exhibit w/ Mark S. Kornbluth

Join photographer Mark S. Kornbluth for a visual exploration of NYC's Broadway theaters at Cavalier Galleries!

While the heydays of traditional manufacturing in Brooklyn are long gone and many of the old warehouses and factories have now been converted into lofts and artist space, a more urban, high tech version of manufacturing still exists in the city. Once one of the nation’s most prolific ship manufacturing facilities, today the Brooklyn Navy Yards is a nationally acclaimed industrial park that serves as a model for modern, industrial development. The Yard is home to over 330 diverse businesses, employing over 7,000 people and generating over $2 billion in annual economic revenue.

The Brooklyn Navy Yards, also known as the The United States Navy Yard, and the New York Naval Shipyard, first started off as a facility for manufacturing merchant vessels after the Revolutionary War. Then, in 1801 it was purchased by the U.S Navy, and became an active Navy shipyard in 1806. Throughout the years the Yard produced some of the countries preeminent battle ships, including USS Maine and USS Arizona. The Navy Yard was decommissioned in 1966 as part of a project that sought to reduce costs through the closure of unneeded military facilities. While the government initially refused to sell the Yard to the city, the facility was ultimately sold 18 months later during the Nixon administration. The Yard was leased by Seatrain Shipbuilding for a brief period, before the era of ship building in Brooklyn came to an end in 1979.

Atop Rooftop Reds in the Brooklyn Navy Yard

Today the Brooklyn Navy Yard has become a bustling mecca of innovative manufacturing and tech startups in New York City. The businesses that are based in the Yard include Brooklyn Grange, a sprawling 65,000 sq. ft rooftop urban farm that employs sustainable agriculture methods; Rooftop Reds, the world’s first commercially viable rooftop vineyard; Crye Precision, which makes an assortment of gear to protect soldiers in combat – including boxers with Kevlar panels to protect the genitals and inner thighs; Duggal, a printing company which has recently expanded into tech manufacturing with street lights powered by solar panels and wind turbines. Another fascinating and exciting startup that we recently visited is the innovative motorcycle startup Vanguard Moto Inc. We sat down with David Wax from Vanguard to discuss the incentives behind the start up and the company’s prospect.

Photo by Vanguard Moto Inc. 2016

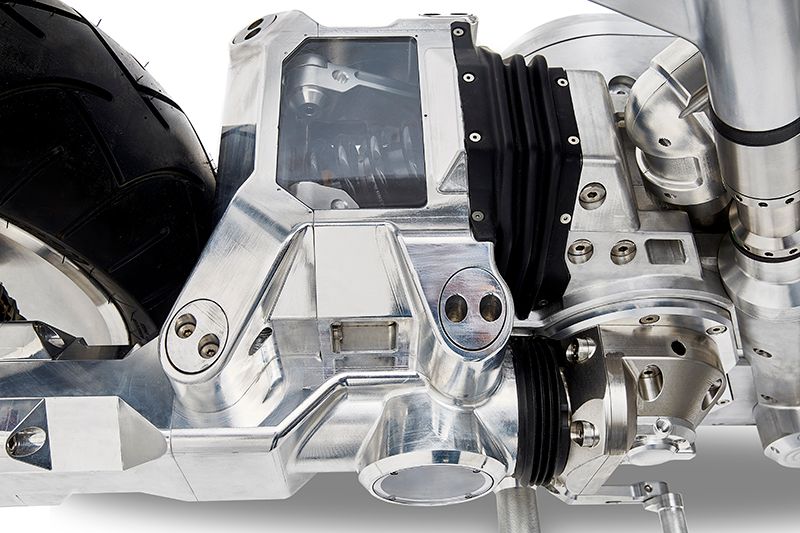

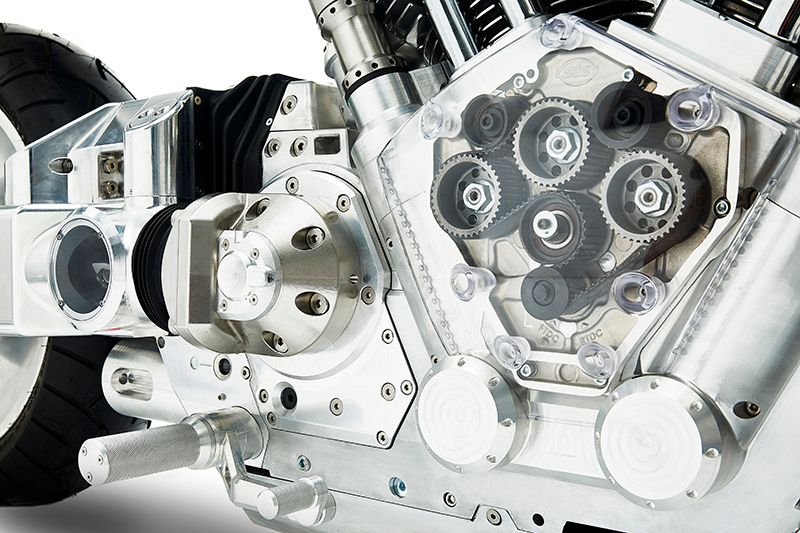

Vanguard Moto Inc. is a premium motorcycle design and manufacturing company looking to “disrupt the premium motorcycle market with their contemporary design and modular assembly process.” The company was founded by entrepreneur and former consultant and supply chain expert Francois-Xavier Terny, and motorcycle designer and engineer Edward Jacobs. Both men were involved in the motorcycle market, where they saw “a gap in the motorcycle market in the premium segment,” according to David Wax. Jacobs and Terny believed that there are no real options in the premium range (between $30,000 and $50,000). “The only motorcycles you could buy are $15k-$20k motorcycles with $15k-$20k of accessories strapped to them.” Vanguard’s motorcycle is estimated to cost $30,000 of purely design and bike components, rather than accessories.

Image by Vanguard Moto Inc. 2016

Jacobs, who also had some new contemporary ideas for motorcycles, formed Vanguard Moto Inc. in 2013 with Terny. Today Vanguard has a working prototype that they have tested. The prototype is a testament to the contemporary design that Vanguard strives for. As Wax says, “rather than put plastic around the motorcycle to make it look nice, we’re actually designing the motorcycle to look nice in its purest form.”

Image by Vanguard Moto Inc. 2016

The bike has a fully digital dash port, and LED lights that are integrated into the bike and articulate out of the bike. Unlike most bikes which utilize a chain to power the back wheel, Vanguard’s design employs a shaft. The designers also opted to forgo the traditional exhaust design in favor of one that is integrated into the crank case. Wax says, “the idea was to not have the exhaust as a design element.” Another feature of the bike is its modular assembly. The bike consists of three parts that can be assembled with five bolts and three electrical connectors. The result of this contemporary design is an innovative bike that has $30,000 worth of pure, essential design components.

Image by Vanguard Moto Inc. 2016

Image by Vanguard Moto Inc. 2016

Vanguard is currently in the process of making some modifications and refinements to their prototype, which they were able to test-ride around the streets of the Brooklyn Navy Yard. The estimated start of production for the bikes is mid-2018. Manufacturing work will take place in the Navy Yard, and Wax says, “Right now we have space reserved at facilities just over there [in another building in the Yard] for full production manufacturing.”

Image by Vanguard Moto Inc. 2016

Finally when asked why they chose the Navy Yards as their startup’s venue, Wax says, “You have some of the best design and business minds in the world. You also have a facility that is set up specifically for this [manufacturing and startups].”

Wax further praises the Navy Yard, saying “The Navy Yards really makes this possible. If it wasn’t for the Navy Yards we’d have to be located somewhere else. The Navy Yard is very friendly for what we’re doing.”

Photo by Vanguard Moto Inc. 2016

Photo by Vanguard Moto Inc. 2016

Photo by Vanguard Moto Inc. 2016

Discover more about Vanguard Moto on the company’s website. Next, read about the Top 10 Secrets of the Brooklyn Navy Yard.

Subscribe to our newsletter