Last-Minute NYC Holiday Gift Guide 🎁

We’ve created a holiday gift guide with presents for the intrepid New Yorker that should arrive just in time—

The prevailing architecture at Columbia University’s new Manhattanville Campus is one of the starchitects’ imagination. The initial buildings — the Jerome L. Greene Center, the Lenfest Building and the Forum — were designed by Renzo Piano, who also created the master plan with SOM. The forthcoming new Columbia Business School facility will be designed by Diller Scofidio + Renfro with FXFOWLE Architects as executive architect.

But long before the arrival of Columbia to Manhattanville, the University had long been operating the country’s only nuclear safety testing facility in Prentis Hall at 632 W 125th Street, in a former Sheffield Farms pasteurization facility and milk bottling plant that was built in 1909.

Inside the control room, Victor Carrano electrical engineer in center, with engineers Carlos Fighetti and Alain Kaam. Photo courtesy Victor Carrano.

The stately white terra cotta building stands out amidst its glassy neighbors on the edge of the Manhattanville Campus, a reminder of a time when this neighborhood was filled with industry and services that supported, or were closely reliant, on the freight railroad and ferries that ran along the Hudson River. According to industrial archaeologist Mary Habstritt, the three dairy companies operating here — Sheffield Farms, Borden Dairy and McDermott-Bunger —controlled 61% of the dairy business in New York City.

The lobby of Prentis Hall

The Columbia Daily Spectator reports that Sheffield Farms processed 15,000 bottles of pasteurized milk every hour in this facility on 125th Street that was “known for its cleanliness and its family-friendly facilities tours.” Today, you can still see the wide stretch of ground floor windows which allowed passersby to look in on the process, an innovative move intended to provide transparency and trust. Tainted milk had been poisoning children for decades from the start of the Industrial Revolution and pasteurization changed all of that. The garage door openings are also still there, where horse and carriages and later trucks would pull in to load up on the bottles. You can still see the cobblestones inside the interior driveway of the building and incredibly, in the stairwell, possible Guastavino tiling.

Remnant cobblestone paving inside the building where horses once walked

We took a visit to Prentis Hall with Victor Carrano, a native New Yorker and long-time Untapped New York reader who worked in the Heat Transfer Research Facility as an electrical engineer for seventeen years starting in November 1987 until it was closed down in 2004. He is one of only two electrical engineers who have ever worked in the history of the lab. Carrano was responsible for power, control, instrumentation and data acquisition, and remembers the layout of the facility like it was yesterday. In fact, he followed in the footsteps of his father, who had worked in the research facility as a technician since 1956. There’s been a Victor Carrano at the facility for nearly the whole history of the lab, which became operational in 1953, he jokes.

Columbia University’s Heat Transfer Research Facility predated the creation of any national labs and has been responsible for testing “generations of nuclear reactor fuel assemblies,” according to Harry Hutchinson, author of “Powering Down” in an article for Mechanical Engineering. The lab first operated under the Atoms for Peace program started by President Dwight D. Eisenhower in the 1950s.

The testing facility closed in 2004 and the building is now home to the School of the Arts and the Music Department at Columbia. Incredibly however, most of the areas that were involved with the testing have simply been closed off and locked, but not repurposed yet even after sixteen years. White signs with red lettering in all caps read “RESTRICTED ACCESS. COLUMBIA UNIVERSITY OPERATIONS ONLY.” Some more DIY signage in the building remind people that the equipment is not in use.

As I walked around with Carrano, he found labels he had made decades ago still on the walls. Narrow lookout windows that once offered a view into a former control room were piled with cardboard boxes, but still extant. A new bathroom was put in the former tool kit closet.

Former lookout window to control room

Columbia University bought the building in 1949 and the lab was running by 1953. It functioned within the School of Engineering and Applied Science, whose dean, the physicist John R. Dunning was a key member of the Manhattan Project. Dunning was the scientist who built the cyclotron in the basement of Pupin Hall at Columbia that first split the uranium atom in the United States in 1939 (that relic was scrapped in 2007).

Most of the testing done in the Heat Transfer Research Facility were for industrial contracts with civilian nuclear power companies like Westinghouse, but the lab also supported the U.S. government, testing for the nuclear submarines in the Navy and other government reactors.

As we walked past components of the lab that Carrano was excited to see still around, he explained how the testing worked. “You’ve seen some pictures of nuclear reactors. It’s a series of rods, you know, in an array like 200 something. Well, we would test a representative component of that. So it’s five by five, for example. The biggest we ever did was nine by nine, that requires more power.” These tests would demonstrate, through extrapolation, how the full scale fuel bundle would perform safely in operation. Direct current, which is more even than AC current, would be applied to simulate the heating of uranium.

Victor Carrano in the basement of Prentis Hall

Carrano continues that the test most commonly performed by his team was the critical heat flux test, which would determine at which point a reactor might burn out and cause a melt down, Chernobyl-style. He says, “Before any new fuel by any vendor was given the okay by the NRC [the Nuclear Regulatory Commission], they had to go through a number of tests. One of them was this critical heat flux test. So we would push, push it to see where it would fail in real life and then they knew that this was the boundary and then they back off, and this would be the operating range.

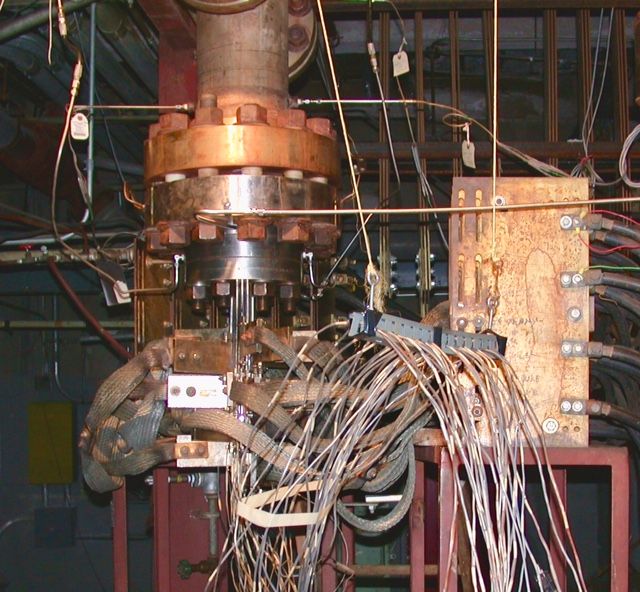

The bottom of the “test section” in the basement level of Prentis Hall. Photo courtesy Victor Carrano.

He adds, “While performing the tests, I would sit at the orange console and control the power to the “rod bundle.” The two round knobs controlled the output of all six generators. The left controlled the four on the first floor and the right the two in the basement. It was nerve-wracking because the two sets of generators had very different characteristics so as I was raising or lowering the total power, I had to watch those individual bar graphs so none of the generators were overloaded.

Behind the orange console was a device that displayed the temperature inside the rods. As I slowly raised the power, I had to watch about 80 individual temperatures. At some point, one or more would rise very rapidly. I would then call out, “That’s it!”, and then lower the power quickly. That established one data point for the customer – the fuel manufacturers like Westinghouse or Combustion Engineering. They presented an entire program of 100-150 of these data points to the Nuclear Regulatory Commission for approval. Once approved and the fuel available to nuclear plant operators, our data established the safe operating margins. The two other engineers controlled the conditions mimicking those in a real reactor – temperature, pressure and flow.”

The former dairy building, though not constructed at all for nuclear testing, fit the bill perfectly. The floors are thick, in some places more than a foot and a half tall, designed to withstand the weight of the bottles of milk, the horses and carriages that would pick up the inventory, and the equipment. It has a running freshwater stream below it, which the lab could pipe water up directly from wells to cool down the process. “When you’re going to generate so much heat, you’ve got to cool so much heat so if they had to take city water, it would have been crazy.” The fresh water would have ordinarily gone to waste, Carrano says because it had to be drained constantly. During the a drought in the 1970s, trucks came to Prentis Hall to pump out water to distribute to the rest of campus. In the basement today, you can still hear water running.

As we took a look at the electrical panel that still distributes power throughout the building, Carrano says, “My Con Ed rep said at the time, ‘Your place is unbelievable!’ This little four story building has three 13,000 volt feeders coming in. One was just for the building, which is very ordinary, but then we had two just for our experiments, just to feed our generators.”

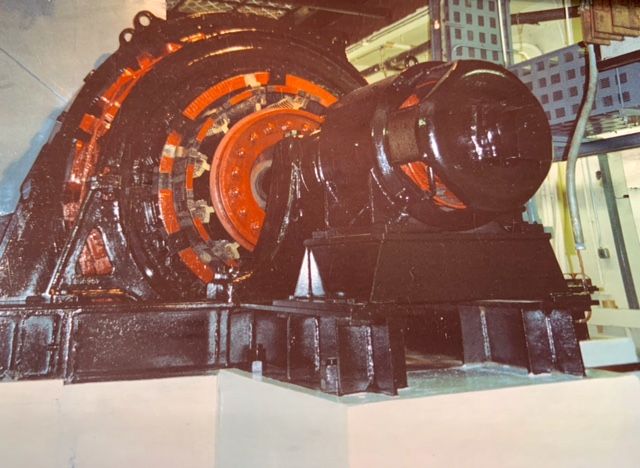

Behind a closed area was where the motor generator was located. (Perhaps it was still there, but we could not confirm). Says Carrano, “It’s a huge 5000 horsepower motor. And two generators on the same shaft, and then two more little auxiliary generators on the end of that. That’s the first one they got when they got started. They got that from the Oak Ridge National Lab.”

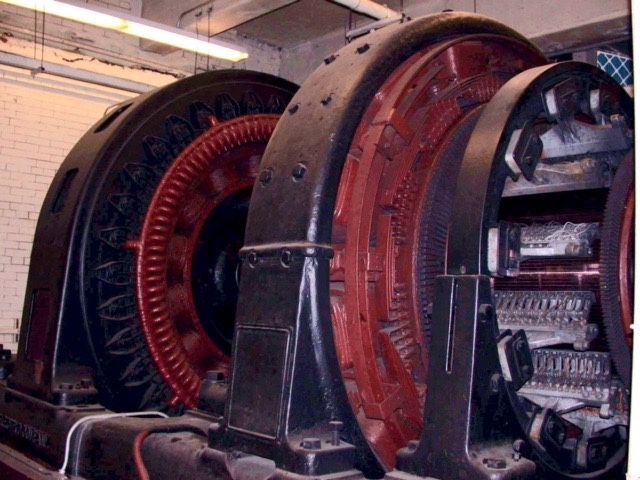

The rotaries. Photo courtesy Victor Carrano.

It was so powerful that the Eighth Avenue subway would feel a small “hesitation” during the 15 seconds when the motor was starting up, since the high voltage feeder that supplied the motor in Prentis Hall was also used by the subway! It was determined that the small delay in the subway was manageable. This is the generator the facility worked with for twenty years until the 1970s, when a new grant from the Atomic Energy Commission allowed the lab to get four more motor generators.

The generator that came from Oak Ridge. Photo courtesy Victor Carrano.

“That was my primary responsibility,” Carrano says, “to keep the generators going, to do whatever you can to keep them going. And we would go as high as 15 megawatts. My [Con Ed] rep told me we were the single biggest customer in terms of demand after the World Trade Center. We were number one for a while.”

The basement today

As the world entered the new century, the Heat Transfer Research Facility was still operational but per square footage, it wasn’t the most economical. The lab was generating less than it used to, although Carrano says it was very profitable for Columbia for a long time, generating up to $2 million a year approximately. It takes a lot of real estate to run such a facility and Columbia University needed more space.

On the upper floors, you can still see the old offices where billing and administration were done. Not much has changed here, including the translucent glass panels of the offices and an old walk-in safe that once stored records and valuable equipment. It’s now neatly stacked and organized with office supplies. An old periodic table, framed, sits perched against a wall, a poignant reminder of what this building once was and how often, history gets retained through inertia sometimes. Of the people who hold the history of this building, Carrano says, “So many of them have passed now. It’s sad. There are only a few of left us now, the younger generation.”

Next, check out more Secrets of Columbia University.

Subscribe to our newsletter