Although the name has changed from the Bush Terminal to Industry City, the team that now manages the industrial buildings on Second Avenue between 28th and 65th Streets in Sunset Park, Brooklyn (covering more than 200 acres of waterfront property) is hoping to once again create a “hub of commerce and culture” at the site.

The original terminal was founded in 1890 by Irving T. Bush on the site of his father’s oil business. The initial development started with a single pier, a warehouse, a railroad engine and a towboat. The first shipments to arrive at Irving’s terminal were cases of bananas from Jamaica and barrels of hay from Michigan. However, this small terminal quickly became the largest freight depot, loft building and warehouse conglomeration in New York City. In its heyday the terminal had over 30,000 employees who were responsible for manufacturing an array of products, including the famous “Topps” brand chewing gum and baseball cards.

Irving T. Bush’s original mission to establish a complex that would transport and manufacture goods and services was upheld for many years. The Bush Terminal saw a decrease in commerce for several years when four of the piers were deemed brownfield sites. However, in 2006, a $17.8 million grant was approved to clean up the site and redevelop the area.

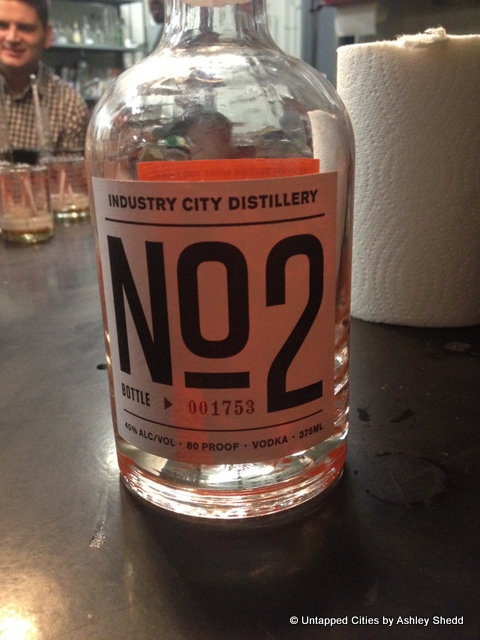

Dave Kyrejko, Max Hames, Peter Simon, Rich Watts, and Zac Bruner are the co-founders of Industry City Distillery and its parent company, The City Foundry; together with Ryan Weaver, who manages outreach, and Elizabeth Murrenus, their resident “Microbe Master,” they make up the body and brains of one of Brooklyn’s newest distilleries. This group of individuals has brought their backgrounds in art, engineering, biology, design and business to create Industry City Distillery’s “No. 2” vodka, which challenges the misconceived perception that vodka cannot be enjoyed “straight up” just as a high-end whiskey or rye can be.

Industry City Distillery is one of several start-ups that have had the opportunity to utilize the affordable and manageable space offered in Industry City, and to combine the creative forces of several individuals to come up with a product that truly defines craftsmanship, chemistry and collaboration. In October, a group led by the Historic Districts Council, an organization that provides educational events for preservation-minded people, headed to the 6,000-square-foot distillery to learn a little history, make connections, share ideas and raise a glass in celebration of New York City and its heritage. We got a special tour that included cups of tea on arrival, a look at the interesting collection of hard hats and other safety gear worn in the space, and a peek at the truly beautiful antique printing press that is used to produce the labels and other printed materials for ICD and their partner organizations.

For the record, the engineering, science, fabrication and design processes that go into creating their product cannot be simply explained. To gain a full understanding of the craftsmanship, dedication and talent behind ICD, a tour is mandatory!

DIY: Industry City Distillery takes the “Do It Yourself” mentality to a level that many of us strive towards. They have built a distillery from reused and repurposed materials, carefully designing and building everything from scratch; walking through their space will definitely have you conjuring images of Rube Goldberg contraptions and Young Frankenstein.

So, why have they decided to create more work for themselves? Their combined knowledge and skill sets makes them capable of creating everything, including their machinery and yeast, by hand. This, in turn, is often more cost efficient and allows them to fully test and improve each step of the distillation process. Their ability to carefully manipulate the taste and quality of their vodka is unlike many other distilleries, and the end product is ultimately of a higher caliber. To understand the gist of this, take a look at Industry City Distillery’s website, which includes phrases like “custom-built glass bioreactors in a continuous fermentation line” and “high-efficiency steam powered stripping still”. To put it simply: the flavors produced by yeast during fermentation largely determine how their final product tastes. Building the equipment themselves has allowed the distillery to observe, learn and control the yeast (a strain first isolated on sugar beets) to discover what works and what does not work when it comes to the taste of “No. 2” vodka.

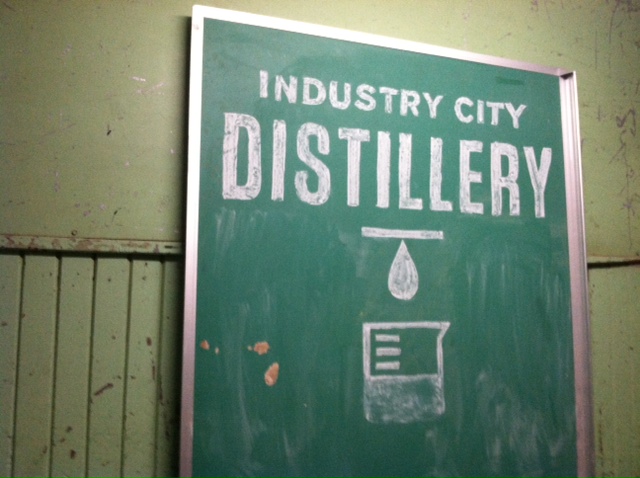

The history of the area is noticed once you abandon the asphalt under the Brooklyn Queens Expressway and start walking down the cobblestone streets that line the roads between the buildings of Industry City. This feeling was continued as we were greeted by our “tour guide” Peter, sporting his gray Industry City Distillery coveralls. He walked us down the cold, concrete hall leading us to the freight elevator that features a chalkboard reading “Industry City Distillery”. This industrial elevator lift is often referred to as the “living room” because it is the size of a room, and usually full of furniture or materials being brought into the space. (It also usually has a bench inside, for guests to sit on as they ride upstairs.) Once you enter the space you are welcomed by the aroma of coffee and the vision of cans of CafeBustello sitting upon the cabinets that line the walls of the kitchen. The space is full of interesting trinkets, plants, glassware, hardware and random tools along with everyday items you might find in your own home.

This living space is the façade of what hides behind the walls of the Industry City Distillery. A lab, a printing press, a fabrication shop and a distillery await along with a group of dedicated, knowledgeable, creative and welcoming individuals.